Vickers Vildebeest Mk.III

Vildebeest NZ102

The Vickers Vildebeest was a very large 2-3 seat all-metal biplane, typical of those produced in Britain during the inter-war period. The RNZAF operated 39 Vildbeests between 1935-44, of which NZ102 is the most complete remaining airframe. For more history on NZ102, click here.

Project overview

The remains of Vildebeest NZ102 have been part of the collection at the Air Force Museum of New Zealand since 1986, along with minor components from several other RNZAF Vildebeests and Vincents (a general purpose variant of the Vildebeest). What makes this so special is not only that it represents the only significant remains of any ex-RNZAF Vildebeest, but that they are the only significant remains of a Vickers Vildebeest to be found anywhere in the world.

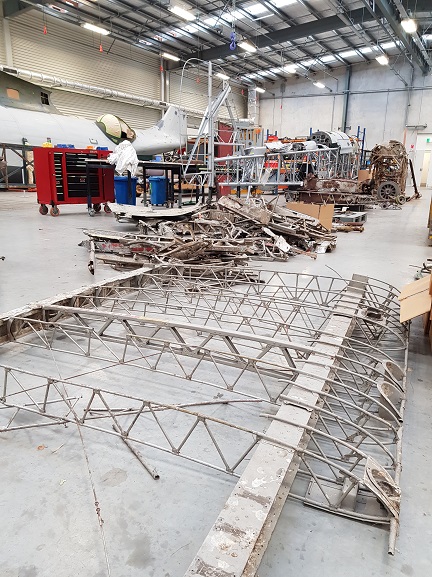

Restoring an aircraft of such complexity and scale is difficult enough when you have a complete airframe and all the necessary engineering drawings, but to attempt it when all you have is wreckage, a few minor technical references and whatever information you can glean from period photographs, is harder still. Some progress has been achieved in the past using the principle of reverse engineering, where the original structure is painstakingly disassembled and examined in order to learn how to re-construct it and this has been successful in helping to rebuild an almost complete fuselage frame.

To a degree, the outcome of such a difficult project is unpredictable, but it is hoped that a full skeletal airframe can be assembled using as much original structure as possible, which would make an impressive addition to our collection of exhibited aircraft. As the project progresses, we will gain a clearer picture of what might be achieved beyond that. The rarity and historical significance of the Vildebeest means that it is one of the most important military aircraft held in a museum collection anywhere in New Zealand, and we are thrilled to be able to make this challenging project a priority focus.

NZ102 can be viewed in the Conservation Workshop on our daily, free Behind the Scenes tours.

What is currently happening?

Update 6 October 2022

The project took a significant step forward recently. Following the completion of the lower centre-section frame and some initial conservation work on the undercarriage struts, these components were mated together with the fuselage for the first time. The alignment between these three major structural elements is key in ensuring the correct rigging of the whole airframe going forward. Sadly, this arrangement is only temporary, but it has given an exciting glimpse into the sheer scale of the Vildebeest and of what’s to come as this project progresses.

Update 3 March 2022

Up until now, the majority of the work on the jigsaw puzzle which is NZ102 has gone into identifying the individual items we have available from recovered structure. This process is very time consuming and involves removing the surface contaminants and surface coating to locate the stamped part number on each item which then can be used to identify if that item is indeed a Vildebeest part and where it is located on the aircraft. Thanks to the work of our small team of staff and volunteers, we have a comprehensive list and quantity of all the items required to build up the upper and lower centre sections of the aircraft.

Over the past three months, the team has stripped down the top and bottom centre sections to individual parts and carried out conservation treatments on each. Corrosion on some of the parts resulted in the need to manufacture new ones, using the old parts as templates. New spar caps were made for both front and rear spars on the upper and lower centre sections, along with sections of the compression struts, several joining plates, and fittings.

The lower centre section spars and compression struts are now pre-assembled and installed in a jig awaiting the internal bracing tubes to return from conservation treatment, after which they will be fitted to ensure the section is held square for final assembly. When this is complete, work will begin on the internal ribs and other panels to complete the lower centre section.

Meanwhile, the upper centre section spars are being reassembled while we wait on the internal bracing, and a start is being made on the undercarriage and support structure, which will be conserved over the next few months prior to assembly.

Update 6 August 2021

We’re pleased to be able to share that the Vildebeest restoration has now progressed to the production phase of the project. Stage one is the lower centre section, in particular, the front spar which is the structural member that carries several important stress loads. The undercarriage is attached to it from below, the fuselage is directly attached to its upper surface and the outer wings are attached at each end. Following a detailed inspection, it was determined that the spar, in its current condition, would not be suitable to reuse as the lower cap has a number of previous repairs and the web stiffening plates have severe exfoliation corrosion, and all of this combined, compromises the strength of this crucial airframe member. The Museum’s policy is to retain as much original material as possible, but obviously, structural integrity must be the main aim.

A new lower spar cap has been manufactured using the old cap as a template, once this has been temporarily refitted we will remove the web plates and manufacture replacements. These will be refitted using a jig to ensure that the spar remains straight and that all overall dimensions match the original. Once this is completed, the spar end fittings will be removed and their surface finish restored before the entire spar assembly is permanently reassembled.

Meanwhile work has also progressed on perfecting a method for the forming of the curved channel sections required for the wing ribs caps. The use of a basic wooden mould has produced some satisfactory results, suggesting that there is potential for this task to be completed in-house. However, the number required and the complexities of consistently forming multiple identical caps means that we may still look to contract out this process.

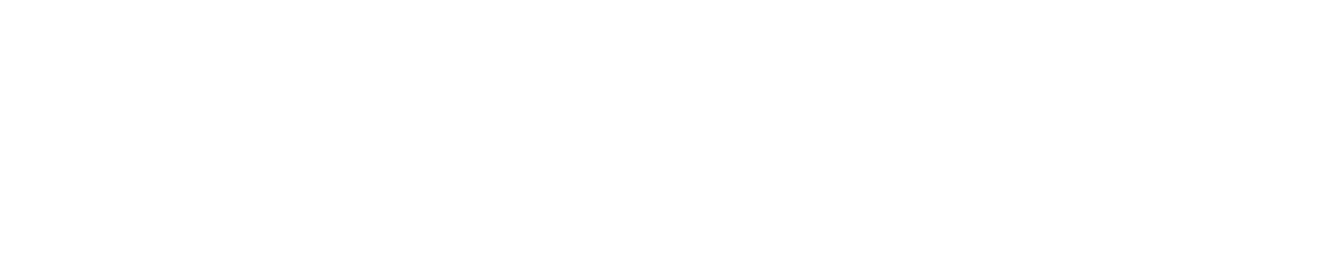

Update 2 December 2020

Now that the major structural parts that will be used on the build have been identified, we have been able to try offering up some parts for comparison. With no engineering drawings to guide us and many of the part numbers that were stamped on components illegible due to corrosion, we’ve done a ‘dry fitting’ of the wing centre sections to the fuselage to help us identify the exact locations of components like the diagonal centre-section struts. While they look very similar, they have subtle differences. With the lower main planes in position, the 15m wingspan helps you appreciate the size of this aircraft, especially when you factor in that the upper centre section will sit at almost 4.5m high when the aircraft is completed.

Meanwhile, our Research Team is making great strides in uncovering information about NZ102’s operational life, including details of the pilots who flew it. Read more about what has been uncovered, in our blog, here.

Update 24 July 2020

Currently, the team is in the midst of the initial project scoping and research phase. An inventory and inspection is being undertaken of the spares and structure currently in the collection, to determine the extent that can be reused or restored, and gaps identified. Meanwhile, our Archives team is conducting in-depth research into the service history of NZ102, so that we may be better placed to share the story of this unique aircraft.

Can you help?

If you believe that you may have parts or information that would be useful to the restoration of Vildebeest NZ102, our Technical Conservation team would love to hear from you. Please get in touch via the link below.